Electroforming as a basis

I make jewelry from plated natural materials, and its creation is a multi-stage process. Each stage requires a different method - from chemical preparation, through plating, to classic goldsmithing - and combines the precision of technology with the sensitivity of the jeweler's hand.

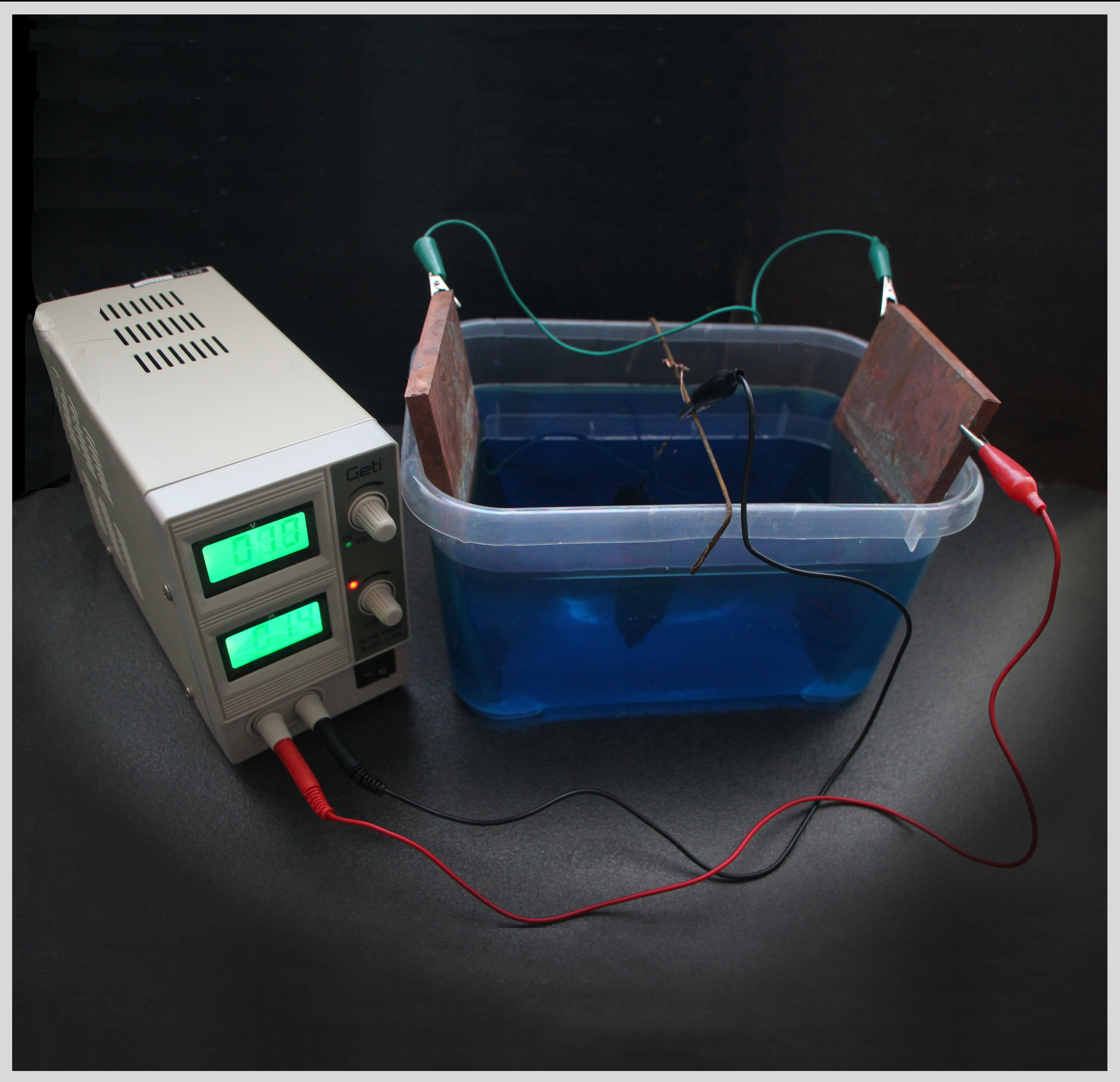

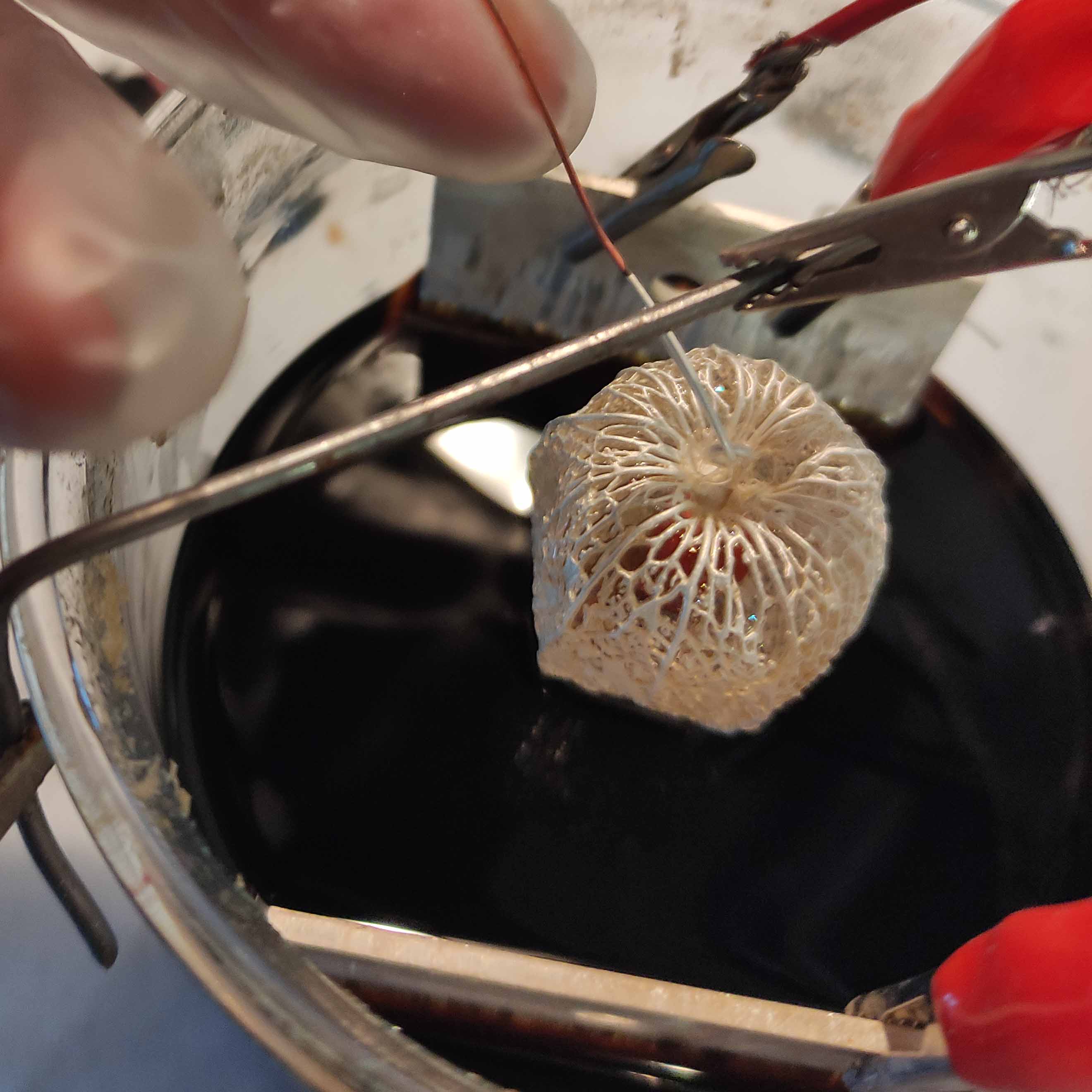

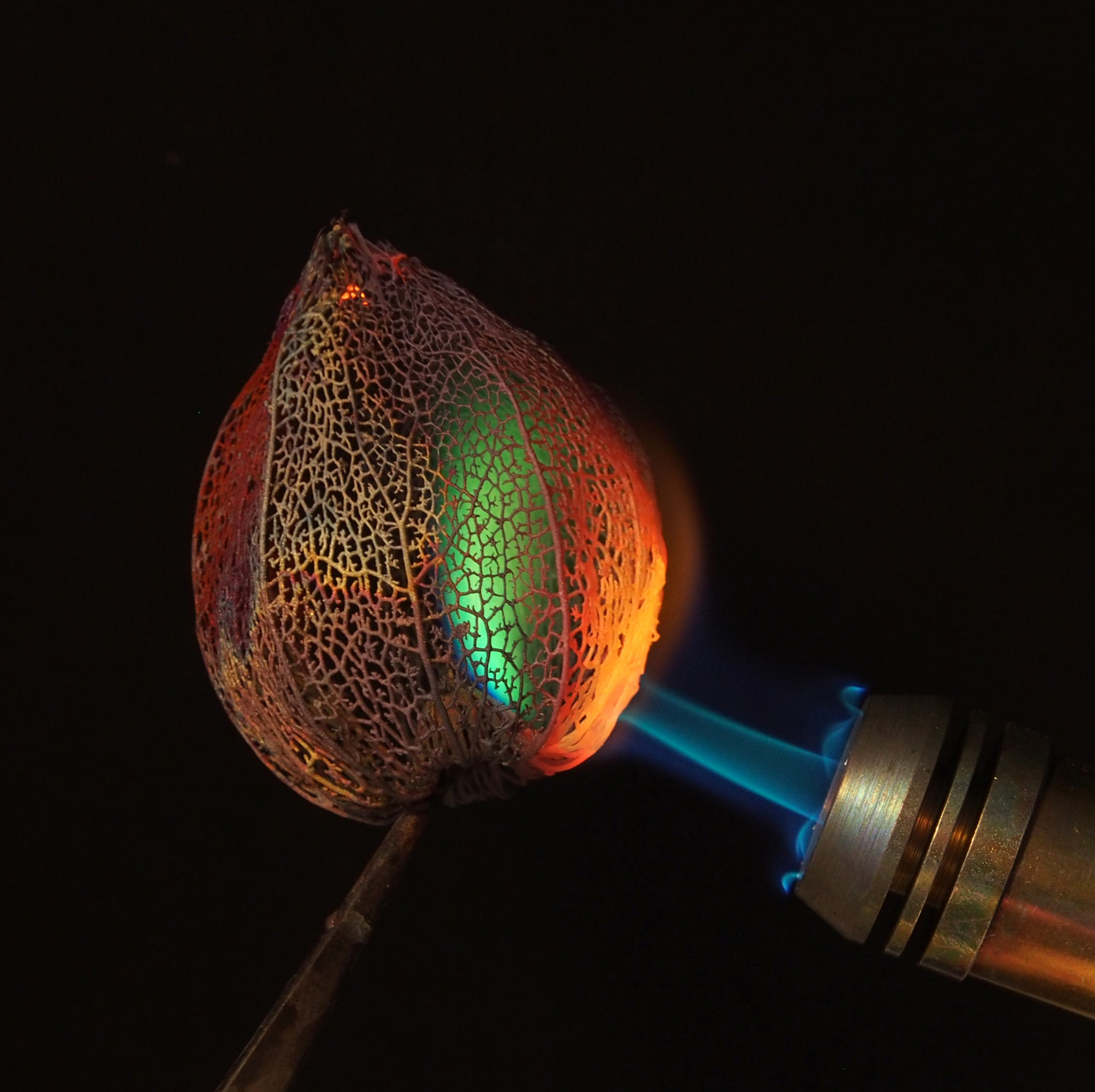

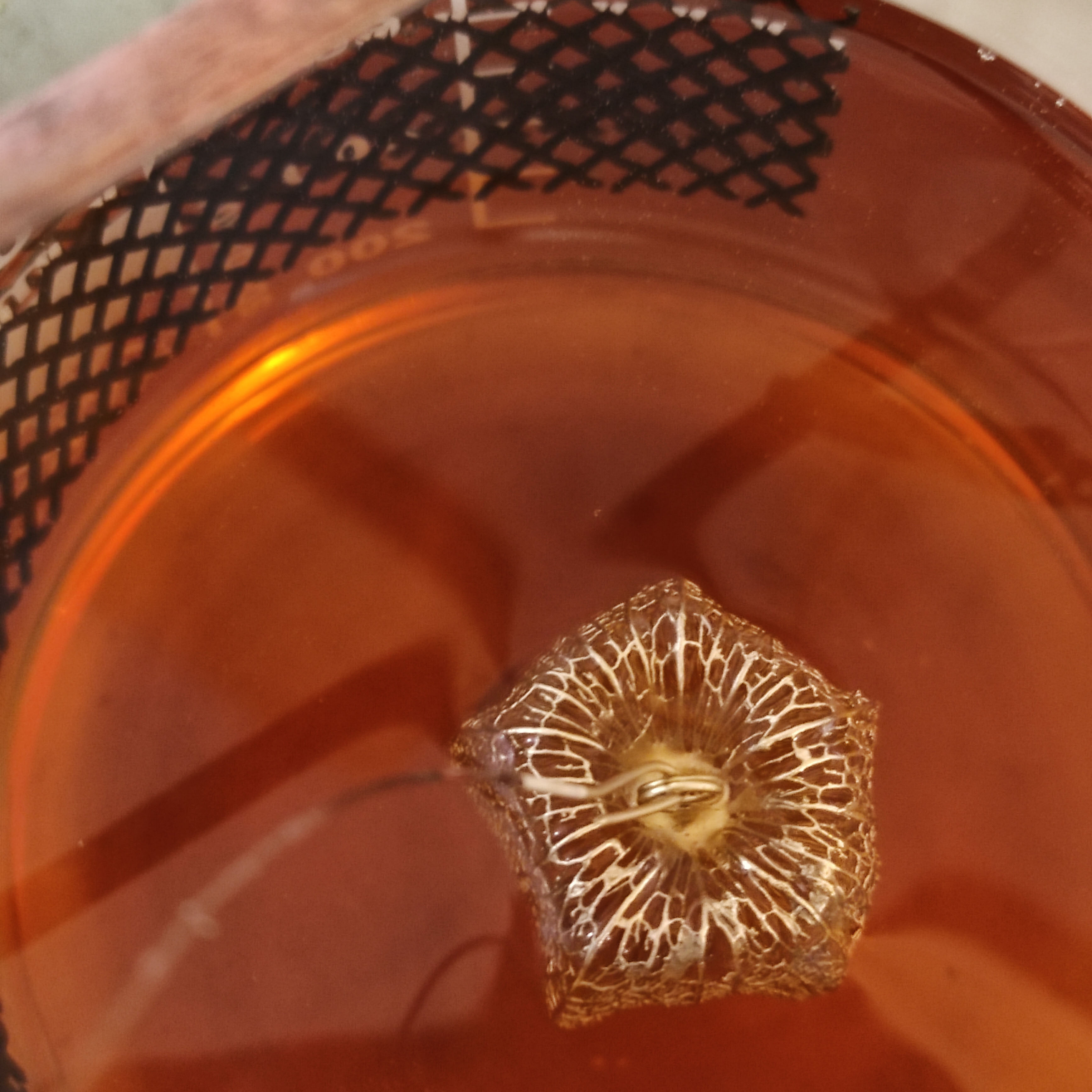

The basis of my work is electroforming - a unique technology that allows you to transfer almost any material to metal. In a galvanic bath, metal ions are deposited on the surface, creating a solid metal casting that perfectly preserves the relief and texture of the original object.

Electroforming has its roots in the 19th century, when it was used to produce art objects, jewelry, and copies of sculptures and historical artifacts. I take this technique further: I continue the tradition, but I connect it with modern research, experimental procedures, and contemporary jewelry design.

The basis of jewelry is always a natural product, which can be coated with pure copper or directly with silver and then modified.

Copper electroforming

In the first case (with a copper base), a costume jewelry product is created - but beautifully and artistically processed.

Copper plating is a type type of electroforming and is a very impressive, relatively safe and technically simple process, which, however, requires experience and precision.

I pass on this knowledge in my courses of making copper-plated jewelry and in my book „Kouzla galvanoplastiky“.

However, the work on the jewelry is far from over after the copper plating is complete. The future jewelry may require grinding, polishing, soft and hard soldering, and welding. Since I work with metal created by electroplating, the use of these technologies has its own specifics that require experience and a careful approach.

Precious Metal Electroforming

In the second case (without a copper base), I developed my own methods of applying precious metals to natural products. This precious metal electroforming is my unique know-how, a protected utility model. The jewelry created using this technology achieves a quality recognized by the Hallmarking Office – their detail and accuracy are perfect. It is a complex and relatively expensive process, which is also reflected in the final price of the product, but lovers of unique art will appreciate this value.

And here too, I continue with other procedures:

- I connect individual parts by soldering,

- I create contrast and depth by patinating,

- I add luxurious surface finishes by slicing and gilding,

- I emphasize details by carving,

- I complement the metal base with color accents by chamfering and setting stones,

- I create structural components with precise shapes by casting from wax.

In addition, I specialize in surface finishes with precious metals - silver, gold, rhodium, ruthenium and others. I master both classic galvanic and goldsmithing procedures, as well as my own experimental methods, thanks to which original color and material effects are created.

I have not only many years of experience, but also a professional education in the field of goldsmithing. Thanks to this, I can combine modern experimental approaches with classic jewelry skills that have been tested by entire generations.

The result is jewelry that connects science, history, tradition and contemporary art. They are as unique as the nature that inspires me, and as durable as the metal they are transformed into.

Each piece gains soul and technical precision – from biological basis to metallic reality, without compromise.